Navigation

Clean Coal-Fired Power Plant Test Traps 95 Percent of Carbon

Tests of a new technology for capturing greenhouse gases from coal-fired power plants have achieved 95 percent cuts in a step towards new ways to fight climate change, a Norwegian company said on November 16, 2007.

Tests of a new technology for capturing greenhouse gases from coal-fired power plants have achieved 95 percent cuts in a step towards new ways to fight climate change, a Norwegian company said on November 16, 2007. "It's a breakthrough for us," Henrik Fleischer, chief executive of Sargas technology group, said of tests held since October of a prototype at the Vartan power plant, run by Finnish energy group Fortum in Stockholm.

"A competitive coal-fired power plant with carbon dioxide capture could be built today with this technology," he told Reuters. "It could produce energy at competitive costs."

Many firms are seeking to strip heat-trapping carbon dioxide from burning coal to help nations including the United States and China, the top greenhouse gas emitters, to cut back.

Industries say they would need subsidies for any "clean coal" technology.

Tests by Sargas' five-metre (16 ft) high system of pressurised filters, absorbers and condensers at Vartan -- processing 60 kg (130 lb) of exhaust gases an hour -- are capturing 95 percent of carbon dioxide, Fleischer said.

"This is a complex type of installation and it's good to know it works," he said. The system relies on existing technology adapted from the chemicals industry and would have to be 40 metres tall to work at full scale.

Fleischer said that the capture process costs just under US$20 a tonne of carbon dioxide and that companies would need government help for storage -- perhaps by pumping the gas into offshore oilfields to raise pressure and extract more oil.

In the European Union market, prices of carbon dioxide emissions permits are about 22.7 euros (US$33.30) for delivery in December 2008. Greenhouse gases are almost universally blamed by scientists for stoking warming that could bring more heat waves, floods and rising seas.

|

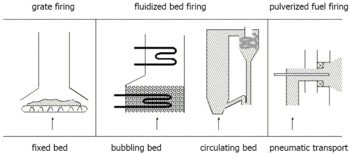

| Combustion systems for solid fuels Image: Wikipedia |

A limitation of Sargas' technology is that the system works under pressure and only a handful of coal-fired power plants so far use the so-called Pressurised Fluidised Bed Combustion technology -- in Sweden, Japan and Germany.

That means it can be used in new plants, including any burning natural gas, but cannot be easily retro-fitted at plants where exhaust gases come out at atmospheric pressure.

"It's not a big technology for existing plants but for future plants it could be interesting ... theoretically you don't need so much energy," said Eva-Katrin Lindman, head of research and development at Fortum Varme.

Among other projects, WE Energy and Alstom Power Inc plan to start a test carbon capture facility at the Pleasant Prairie coal-fired plant in Wisconsin by the end of the year, using a system using chilled ammonia.

Sargas is working with aluminum producers Alcan and Norsk Hydro, French metals producer Eramet and Norwegian group Tinfos on plans to build a coal-fired power plant to supply metals smelters in Norway.

If they win approval as hoped next year, the 400 megawatt (MW) plant could be up and running with full carbon capture at Husnes on Norway's west coast in 2012, Fleischer said. Sargas is in also in talks with other countries.

Coal is the world's number two source of energy behind oil, accounting for about a quarter of all primary demand.

Article by Alister Doyle, Environment Correspondent. Editing by Anthony Barker for PlanetArk November 19, 2007. Reprinted with permission. © Reuters News Service 2007

Note: Video on the existing Pressurised Fluidised Bed Combustion technology Stockholm power plant in Vartan is available on the Horizon International TV Web site at: Goteborg_and_Stockholm.wmv from Horizon International's TV program, "Cooperating for Clean Air" co-produced with Sweden TV 2.

Animation: http://www.ansys.com/industries/chemical-process-fluidized-bed-ani.htm

Related facts from Fortum:

Fortum's production among the most climate-benign in Europe

Environmental key figures in 2006

5.3.2007 15:00

• 84% of the electricity generated by Fortum was free of carbon dioxide emissions.

• Renewables accounted for 40% of Fortum's electricity generation and 43% of heat generation.

• The total use of biomass rose by 22%.

• Fortum Markets is the leading seller of eco-labelled electricity in the Nordic countries.

• Environmental certificates cover 95% of Fortum's business volume.

Heat production

|

| Fortum generates condensing power in the Meri-Pori power plant in Finland Photo: Fortum |

Fortum generates and sells heat in Nordic and Baltic countries as well as in Poland. In addition to district heating, our heat business concentrates on industrial steam, district cooling and waste-to-energy production.

We generate energy in several hundred heat plants and stations and in 21 combined heat and power plants, already in seven countries. In Sweden our heat business is run by Fortum Värme samägt med Stockholms stad, in which the city of Stockholm owns a 50% share.

The core business of the company is to generate and provide district heating in the regions of Stockholm and central Sweden.

In heat generation we utilise a diverse range of energy sources. We aim to increase the amount of biomass fuels used in heat generation and to improve their utilisation in our new power plants.

Our own advanced technology enables the use of biomass fuel in heat production. In 2006, 21% of our heat was generated by biomass fuels.

Fortum is a forerunner in the environmentally benign combined heat and power (CHP) generation. In combined generation almost 90% of the energy can be utilised. The heat generated during the power production is utilised to heat the district heating water or it is used as steam needed in industrial processes. Combined generation reduces environmental emissions 25-40 per cent.

The current role of condensing power in the Nordic electricity production is significant merely as reserve power. Condensing power balances the fluctuation in annual water reservoirs and consumption. The annual generation varies according to the market conditions. For example, Fortum's condensing power generation in 2005 was only 0.2 TWh, while in 2006 it rose to 4.1 TWh.

Fortum generates condensing power in the Inkoo and Meri-Pori power plants in Finland and in the Karlshamn oil condensing power plant in Sweden. Teollisuuden Voima (TVO) is entitled to a part of the generation of the Meri-Pori power plant, as TVO participated in the construction.

A condensing power plant utilises mainly coal and oil in its power generation. Like heat plants, water is heated to run the turbine, which further rotates the generator. Unlike combined heat and power plants, the remaining heat energy is not utilised but condensed with condensing water.

Search

Latest articles

Agriculture

- World Water Week: Healthy ecosystems essential to human health: from coronavirus to malnutrition Online session Wednesday 24 August 17:00-18:20

- World Water Week: Healthy ecosystems essential to human health: from coronavirus to malnutrition Online session Wednesday 24 August 17:00-18:20

Air Pollution

- "Water and Sanitation-Related Diseases and the Changing Environment: Challenges, Interventions, and Preventive Measures" Volume 2 Is Now Available

- Global Innovation Exchange Co-Created by Horizon International, USAID, Bill and Melinda Gates Foundation and Others

Biodiversity

- It is time for international mobilization against climate change

- World Water Week: Healthy ecosystems essential to human health: from coronavirus to malnutrition Online session Wednesday 24 August 17:00-18:20

Desertification

- World Water Week: Healthy ecosystems essential to human health: from coronavirus to malnutrition Online session Wednesday 24 August 17:00-18:20

- UN Food Systems Summit Receives Over 1,200 Ideas to Help Meet Sustainable Development Goals

Endangered Species

- Mangrove Action Project Collaborates to Restore and Preserve Mangrove Ecosystems

- Coral Research in Palau offers a “Glimmer of Hope”

Energy

- Global Innovation Exchange Co-Created by Horizon International, USAID, Bill and Melinda Gates Foundation and Others

- Wildlife Preservation in Southeast Nova Scotia

Exhibits

- Global Innovation Exchange Co-Created by Horizon International, USAID, Bill and Melinda Gates Foundation and Others

- Coral Reefs

Forests

- NASA Satellites Reveal Major Shifts in Global Freshwater Updated June 2020

- Global Innovation Exchange Co-Created by Horizon International, USAID, Bill and Melinda Gates Foundation and Others

Global Climate Change

- It is time for international mobilization against climate change

- It is time for international mobilization against climate change

Global Health

- World Water Week: Healthy ecosystems essential to human health: from coronavirus to malnutrition Online session Wednesday 24 August 17:00-18:20

- More than 400 schoolgirls, family and teachers rescued from Afghanistan by small coalition

Industry

- "Water and Sanitation-Related Diseases and the Changing Environment: Challenges, Interventions, and Preventive Measures" Volume 2 Is Now Available

- Global Innovation Exchange Co-Created by Horizon International, USAID, Bill and Melinda Gates Foundation and Others

Natural Disaster Relief

- STOP ATTACKS ON HEALTH CARE IN UKRAINE

- Global Innovation Exchange Co-Created by Horizon International, USAID, Bill and Melinda Gates Foundation and Others

News and Special Reports

- World Water Week: Healthy ecosystems essential to human health: from coronavirus to malnutrition Online session Wednesday 24 August 17:00-18:20

- STOP ATTACKS ON HEALTH CARE IN UKRAINE

Oceans, Coral Reefs

- World Water Week: Healthy ecosystems essential to human health: from coronavirus to malnutrition Online session Wednesday 24 August 17:00-18:20

- Mangrove Action Project Collaborates to Restore and Preserve Mangrove Ecosystems

Pollution

- Zakaria Ouedraogo of Burkina Faso Produces Film “Nzoue Fiyen: Water Not Drinkable”

- "Water and Sanitation-Related Diseases and the Changing Environment: Challenges, Interventions, and Preventive Measures" Volume 2 Is Now Available

Population

- "Water and Sanitation-Related Diseases and the Changing Environment: Challenges, Interventions, and Preventive Measures" Volume 2 Is Now Available

- "Water and Sanitation-Related Diseases and the Changing Environment: Challenges, Interventions, and Preventive Measures" Volume 2 Is Now Available

Public Health

- Honouring the visionary behind India’s sanitation revolution

- Honouring the visionary behind India’s sanitation revolution

Rivers

- World Water Week: Healthy ecosystems essential to human health: from coronavirus to malnutrition Online session Wednesday 24 August 17:00-18:20

- Mangrove Action Project Collaborates to Restore and Preserve Mangrove Ecosystems

Sanitation

- Honouring the visionary behind India’s sanitation revolution

- Honouring the visionary behind India’s sanitation revolution

Toxic Chemicals

- "Water and Sanitation-Related Diseases and the Changing Environment: Challenges, Interventions, and Preventive Measures" Volume 2 Is Now Available

- Actions to Prevent Polluted Drinking Water in the United States

Transportation

- "Water and Sanitation-Related Diseases and the Changing Environment: Challenges, Interventions, and Preventive Measures" Volume 2 Is Now Available

- Urbanization Provides Opportunities for Transition to a Green Economy, Says New Report

Waste Management

- Honouring the visionary behind India’s sanitation revolution

- Honouring the visionary behind India’s sanitation revolution

Water

- Honouring the visionary behind India’s sanitation revolution

- Honouring the visionary behind India’s sanitation revolution

Water and Sanitation

- Honouring the visionary behind India’s sanitation revolution

- Honouring the visionary behind India’s sanitation revolution